Services

MILLING

To produce complex parts, we have several multi-axis milling centers. As a result, several surfaces of a part can be worked in one step. This reduces handling and improves the accuracy of surfaces to be completed.

Our machinery has a capacity for linear axes 600 x 770 x 805 mm.

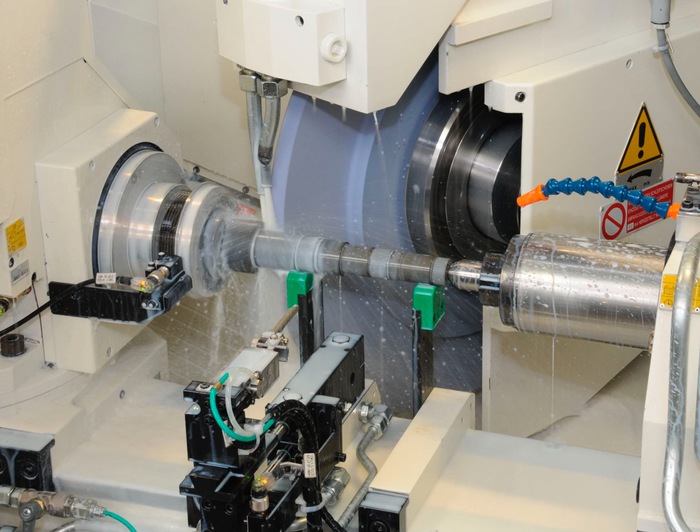

TURNING

We use a range of high-performance CNC lathes that allow us to accurately define the profile of the desired part.

Capacities max. of Turning machining: diameter 730 mm and 750 mm length.

GRINDING

Surface & cylindrical surface grinding (chrome axes)

Drilling – Tapping

Marking parts

Deburring

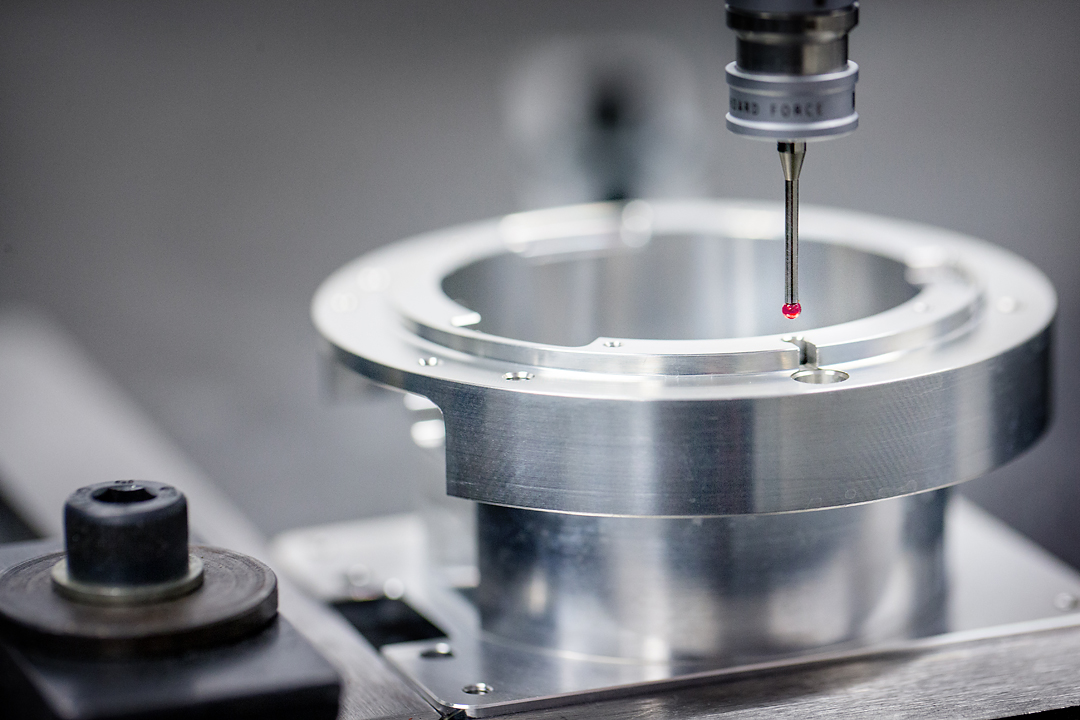

MEANS OF CONTROL

We have an air-conditioned final control room composed of:

• 1 Three Dimensional Measuring Machine

• 1 measuring column

• 1 Surface condition tester

• Traditional measuring instruments (micrometer, buffers, jaw templates, calipers, …)